Pharmaceutical lactose has been used since the 19th century, and has carved out a place for itself in the pharmaceutical industry, becoming a key excipient now found in 60% to 70% of oral medicines. Lactose is the milk sugar and highly present in the whey, a by-product of the cheese production.

Pharmaceutical grade lactose is produced from cheese whey or milk permeate streams by crystallisation and purification before being milled or sieved. Post-crystallisation and milling are an essential step, giving the pharmaceutical lactose different shapes and properties, with a view to guaranteeing optimum effectiveness in all its uses: from the manufacture of medicines to their therapeutic efficacy. Meaning that controlling quality and ensuring a consistency go through rigorous and close management of the crystallization step.

Pharmaceutical lactose, an essential excipient in medicines

Defined by the French Public Health Code and subject to strict regulation, medicines come in a wide variety of forms, depending on the route of administration: oral (tablets, , capsules, etc.), injectable, inhaled, etc. They are composed of an active ingredient with a curative or preventive effect on the body and excipients which mainly acts as a carrier for the active ingredient of the medicine without having a curative or preventive effect2. Excipients play a key role in facilitating the production of medicines, providing them with functionalities and guiding the active ingredient to its target in the body. They must be safe, stable, affordable and widely available1.

Because it meets all these criteria, lactose, a disaccharide of glucose and galactose, is widely used in the pharmaceutical industry, particularly for oral medicines. It acts as a flow agent, a filler, a disintegrant and above all a binder/diluent, retaining or releasing the active ingredient and adjusting the mass of the solid dose3. To meet both the production and efficacy requirements of medicines, multiple forms of lactose are used, each with its own properties1:

-

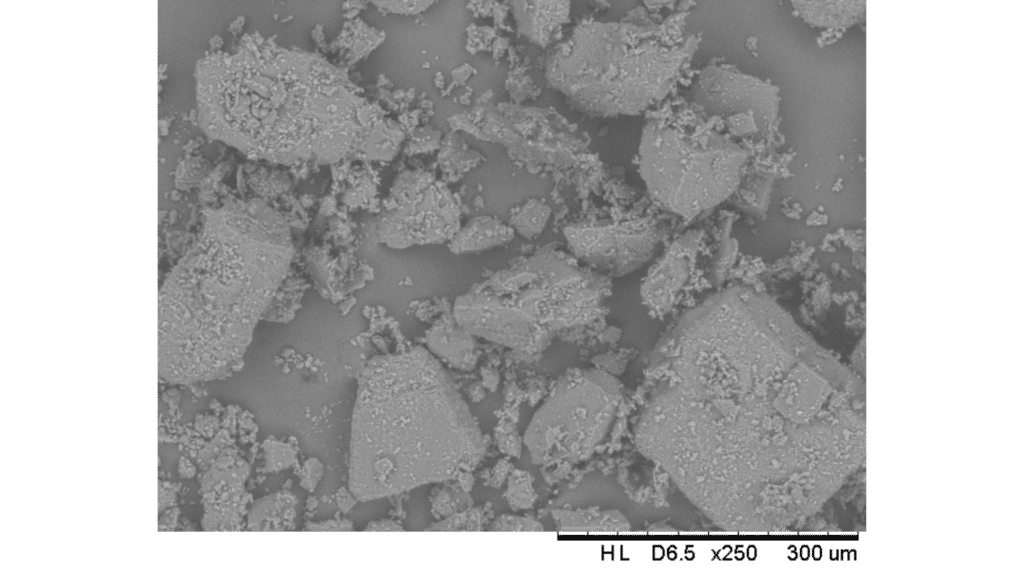

- Milled and sieved lactose is the most widely used form of lactose in terms of volume in the pharmaceutical industry. Two major steps are necessary in its production: milling and sieving. During milling, the larger particles are broken down under the mechanical constraints imposed. Sieving is then used to select a specific particle size. This technique produces a grade of lactose with a particular granulometry. The particle size is qualified thanks to the mesh size units: from the biggest particle to the thinnest one. For lactose, the range goes from 50 mesh to 450 mesh. 200 mesh lactose is the most used for the production of Oral Solid Dose (OSD).

Lactalis Ingredients Pharma is aware of the importance of supplying safe, stable and consistent lactose, and has put all its experience and expertise into the development of Lactalpha, a range of monohydrate milled and sieved lactose.

-

- Another form that is widely used in the pharmaceutical industry is spray-dried lactose. It is made by spray drying a suspension of particles of lactose monohydrate resulting in the formation of agglomerates made up of fine particles bound together by lactose.

-

- Granulated lactose is produced mainly from finely ground lactose monohydrate mixed with water or a lactose solution. This mixture leads to the formation of a porous agglomerate of fine lactose particles.

-

- Anhydrous lactose is a form of lactose mainly made up of crystals characterised by a water content of less than 0.5%. It is obtained by drying the lactose in a double drum dryer.

Pharmaceutical lactose, an excipient that meets the constraints of oral solid dose medicine manufacturing processes

Pharmaceutical lactose in tablets, widespread use

Tablets are a form of oral medicine obtained by compressing powder. They are often encased in a coating or a film4. In the pharmaceutical industry, several methods have been developed for manufacturing OSD (tablets, capsules, sachets…), including wet granulation, dry granulation or direct compression. Each of these methods imposes its own constraints and therefore requires the use of suitable excipients.

Monohydrate milled and sieved lactose: an excipient suitable for wet granulation1

The most common method for manufacturing tablets is wet granulation, especially as it is well suited to low-dose formulations. During the process, the powder undergoes a series of transformations including mixing with water, drying and grinding. The powder obtained can then be formed into tablets. For wet granulation, the most suitable form is milled and sieved lactose, as it combines compaction and flow properties.

Spray-dried lactose, granulated lactose and anhydrous lactose: 3 forms of lactose recommended for direct compression1

The easiest method of manufacturing tablets is direct compression as it is limited to a single step of mixing the ingredients before tableting. Despite being faster, this method presents a risk that should not be overlooked: the possibility that the active ingredient is not uniformly dispersed in the powder. To prevent this problem, the choice of excipient, and especially the form of lactose used, is extremely important. The excipient must have good flow properties to ensure dispersion of the active ingredient, blend effectively with the drug and promote good compaction.

Thus, one of the first forms of pharmaceutical lactose to be developed to meet the constraints of direct compression was spray-dried lactose. Indeed, due to its porous agglomerate morphology, spray-dried lactose can ensure proper uniformity of the active ingredient by retention in its pores. It also has good flow and compaction properties, which are essential in forming solid tablets. Granulated lactose, which is more porous, is a good alternative to spray-dried lactose for this method, since it guarantees good flow, rapid disintegration and effective mixing with the active ingredient. Anhydrous lactose can also be used for direct compression. Its flow, compression and recompression properties, which are made possible by very fine crystal aggregates, allow the creation of harder tablets.

Anhydrous lactose: compaction properties suitable for dry granulation1

Another tablet manufacturing method is dry granulation, which consists of two main steps: compression of the mixture of ingredients between two rollers, followed by breaking and grinding of the compacted product. This method requires the excipient to be recompactible to prevent the compaction between the two rollers from affecting tableting. Anhydrous lactose meets these requirements, as it has excellent compaction capabilities due to its rough surface and high degree of fragmentation. Lactose monohydrate can also be used for dry granulation.5

Pharmaceutical lactose in other oral medicines

Lactose is also used in other oral medicines such as sachets and capsules. The manufacturing methods used are similar to those for tablets, although the final compression stage is replaced by a filling stage. This step requires the excipient to have good flow properties. Because of its specific particle size, milled and sieved lactose is suitable for filling sachets and capsules. Granulated lactose can also be used for these oral forms1.

An excipient involved in the therapeutic efficacy of medicines

Disintegration and dissolution: a key issue for effective therapy

The properties of excipients are essential not only for manufacturing processes, but also for the therapeutic efficacy of medicines. Key properties: the dissolution and disintegration of tablets ensure that the active ingredient is released at the right time and in the right place in the body.

As an excipient, pharmaceutical lactose plays an important role in this release. Its form influences the speed of disintegration. For example, granulated lactose disintegrates the fastest and anhydrous lactose the slowest6. This difference is mainly explained by the solubility of the different forms of lactose: the most soluble forms, such as anhydrous lactose, are associated with greater solubility and therefore with properties that hinder disintegration, such as blocking of drug pores and competition with water.

However, disintegration and dissolution can be modulated by other factors such as:

-

- The solubility of the active ingredient5

-

- The combination with a matrix (cellulose, starch, etc) or disintegrants (PVPP) which can accelerate disintegration 5. That is why OSD production doesn’t imply only one excipient. Medicines often contain three different excipients to ensure the best efficiency of the medical treatment.

Driven by the will to offer high quality lactose, Lactalis Ingredients Pharma proposes Lactalpha, a range of milled and sieved lactose from 50 to 150 mesh. With a view to developing its range in the coming months, Lactalis Ingredients Pharma has invested in a brandnew facility dedicated to the production of lactose. The aim is twofold: meeting the demand for the different galenic forms and the challenges induced by their ways of production.

To conclude, not only does lactose have interesting properties as a filler, binder, or provider of flow to a formulation, it is also sure, affordable, available in many forms and versatile. All these characteristics make it a key constituent present in 60 to 70 % of OSD. Hence the importance to have a pure lactose whose composition is controlled to avoid any possible interaction with active ingredients, or which could affect its stability.

Key word: pharmaceutical lactose

| 1. Paques M, Linder C., Lactose Evolutionary Rôle, Health Effects and Application, 2019 2. Ministère du travail, de la santé et des solidarités, Qu’est ce qu’un medicament ?, 2016 3. Dominici S, Marescotti F, Sanmartin C, Macaluso M, Taglieri I, Venturi F, Zinnai A, Facioni MS. Lactose: Characteristics, Food and Drug-Related Applications, and Its Possible Substitutions in Meeting the Needs of People with Lactose Intolerance, 2022 4. Vidal, Les différentes formes de medicaments, 2021 5. P. H.M. Janssen, A. Berardi, J. H. Kok, A. W. Thornton, B. H.J. Dickhoff, The impact of lactose type on disintegration: An integral study on porosity and polymorphism, 2022 6. Shi C., Zhao H., Fang Y., Shen L., Zhao L., Lactose in tablets: Functionality, critical material attributes, applications, modifications and co-processed excipients, 2023 |