What is pharmaceutical lactose?

For most mammals, milk is the first source of food after birth. Lactose, a disaccharide present in milk, has therefore been a central and essential carbohydrate in our diet for several million years[1]. The concentration of lactose in milk can go to 10% w/w and milk is the only know significant source of lactose. In mature cattle milk, its average concentration is around 4,6% w/w. Apart from this key role in our diets, lactose has also carved out a place for itself in the pharmaceutical and food industries, thanks to its inherent properties. Let’s find out more.

Pharmaceutical lactose: a disaccharide derived from milk

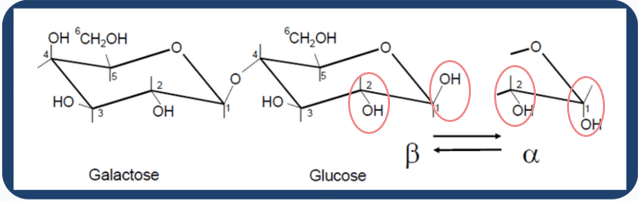

Lactose is a molecule with the molecular formula C12H22O11. It is a disaccharide composed of 2 monosaccharides, D-glucose and D-galactose, joined by a β-1,4-glycosidic bond.

Lactose comes in two anomeric forms, depending on its configuration, referred to as α or β. It depends on the position of the OH group and the hydrogen attached to carbon 1 of glucose. [AB2] In dairy products at 20°C, when lactose is not under its solid shape, both forms coexist, in proportions of 38% of α form and 62% of β form. These proportions change according to the temperature.

Alpha and beta forms of lactose, a disaccharide with two anomeric forms

Lactose can be found in crystalline (solid state) or amorphous (liquid state) form. Both lactose-α-monohydrate and lactose-β-anhydrous are able to crystallise depending on humidity conditions and temperature.

When non crystallised, lactose is called amorphous and can be in its two anomeric forms: lactose-α-amorphous and lactose-β-amorphous. The amorphous form is known as hygroscopic i.e. it has a high affinity for water. On the contrary, the two crystalline forms are non-hygroscopic, meaning that they have a low affinity for water.

Depending on the functional properties required, all or part of the material may be in amorphous or crystalline form. At lactose manufacturing sites, it is primarily lactose-α that goes through the crystallisation process. Lactose-β is oriented to its anomeric form to become lactose-α, by means of mutarotation.

The most common form, in pharmaceutical grade, is the α-monohydrate form. In pharmaceutical industry, especially for direct compression processes, lactose-β-anhydrous can be used.

Pharmaceutical lactose: several forms for diverse uses

The pharmaceutical lactose production process

The extraction process of lactose begins with whey permeate or cheese whey. For lactose α-monohydrate, the most common one, the raw liquid material is processed through different steps: concentration, crystallisation, purifying and drying steps before being milled and sieved.

High purity lactose for pharmaceutical use: an essential, high-quality excipient in the pharmaceutical industry1.

Lactose has been used in the pharmaceutical industry for more than 100 years. Lactose is renowned in the drug manufacture for its versatility, neutrality and wide availability.

The success of lactose as an excipient[AB1] can be explained by: its safety and accessibility, its physical and chemical properties, and finally its versatility. In fact, a wide range of lactose with different properties can be produced, fully adapted and tailored to suit a diverse range of applications and manufacturing methods. For example, lactose can be anhydrous or monohydrate, milled and sieved with different mesh size, from 50 mesh to even 450 mesh. Particle size distribution directs lactose usage and its use in the according galenic, etc.

Lactose powder is used as an excipient in 60% to 70% of Oral Solid Doses, as well as a binder, diluent or bulk agent. It is mainly found in tablets, sachets, capsules or any other oral solid dose.

In pharmaceutics, a specific purity is required

Pharmaceutical lactose i.e. with a purity greater than 99,6% on powder, is also called high purity lactose. It is also characterised by its uniform white colour and low impact on the reactivity of active ingredients. These qualities mean pure lactose is commonly used in pharmaceutics.

The high level of purity is obtained by successive washings that remove residual proteins, ash, and vitamins, such as B2 vitamin. To remove it and obtain pure lactose, a repeated filtration and separation or crystallisation is performed.

As a result, pharmaceutical-grade lactose goes mainly through a double crystallisation to ensure optimum quality[AB1] , with a purity between 98 and 102w/w%.[1] It is also worth noting that, in medicinal products, lactose levels are often low, so intolerance issues are anecdotic.

To sum up, lactose is an essential in the pharmaceutical industry. It is also at the heart of an emerging market, such as the use of lactose derivatives as prebiotics (GOS, Oligosaccharides), as well as new formulation challenges, like regarding next generation treatment or obesity or diabetes solutions ….

[1] IPEC Federation, Pharmaceutical Lactose used in oral preparations is a low-risk excipient, 2021

[AB1]https://pharma.lactalisingredients.com/2024/10/31/lactose-quality-in-pharmaceutical-products-a-comprehensive-overview-of-quality-control/

[AB1]https://pharma.lactalisingredients.com/2024/07/24/the-benefits-of-lactose-as-an-excipient/

[AB2]https://www.lactalisingredients.com/news/blog/lactose-a-multifaceted-disaccharide/

[1] M. Paques et C. Lindner, Lactose: Evolutionary Role, Health Effects and Applications, 2019