Expertise > Production site

Get to know our

lactose production site

Manufactured in Retiers, France, our excipient embodies the reliability and expertise of 50 years of experience in lactose production. Equipped with new state-of-the-art technologies built in 2017, our plant delivers high purity pharmaceutical lactose conforming with the lactose monohydrate monograph of the current Pharmacopoeias (Ph. Eur., USP-NF and JP).

A privileged environment

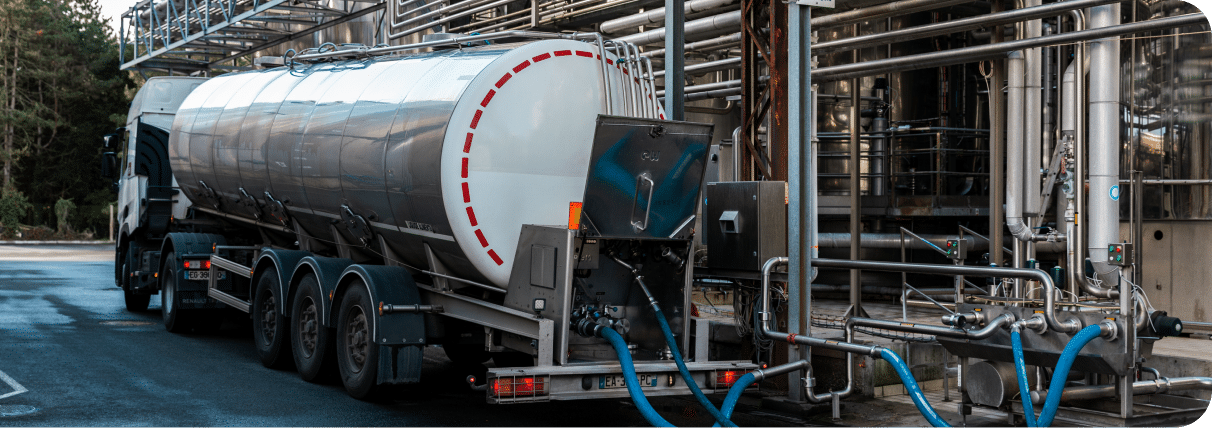

Our pharmaceutical lactose production site is located in Retiers, France. The manufacture is based in Brittany, at the heart of our milk and whey collection area, to facilitate the delivery of raw materials. Once the liquid whey is received, the lactose is produced and shipped from Retiers, to ensure the rapidity and efficiency of the delivery to our clients.

Reliable infrastructures

The construction of the lactose manufacture started in 2016 in Retiers, a site already owned and trusted by the Lactalis Group. Our team members were trained to the lactose process and ready to start working at the inauguration of the state-of-the-art infrastructure in 2017.

While consulting pharmaceutical experts, the new processes were first validated and approved for infant and clinical then pharmaceutical grade requirements to meet the Pharmacopoeias’ standards.

Since then, the lactose production site was perfected to further valorize lactose in the excipients market.

A certified lactose production site

Our company is EXCiPACT certified, a third-party, independent, and high-quality certification standard that evaluates suppliers of pharmaceutical excipients certified ISO 9001, based on their Good Manufacturing Practices (GMP) standards. This certification demonstrates our commitment to quality and transparency in the pharmaceutical supply chain. It showcases our ability to produce reliable excipients for our pharmaceutical customers. Therefore, we are ISO 9001 certified, a globally recognized quality management standard. This ensures efficient processes, customer trust, effective complaint management, and continuous improvement.

Good Manufacturing Practice (GMP) certification ensures that food product manufacturing and dietary supplement activities comply with HACCP rules and regulatory standards such as European Regulation No. 852/2004 and Codex Alimentarius principles.

Moreover, ISO 14001 certification provides a robust environmental management framework, helping organizations control and reduce their environmental impact while ensuring regulatory compliance. This standard also integrates seamlessly with other ISO management systems present at the Retiers site, enabling reliable certification and supporting an efficient, unified management approach within pharmaceutical operations.