We are proud to announce that the factory of Retiers has been assessed and certified as meeting the requirements of EXCiPACT Certification Standard for Pharmaceutical Excipient Suppliers. This certification covers the manufacturing and packaging of Lactalpha, our lactose monohydrate intended to be used as a pharmaceutical excipient. After years of hard work from our teams, especially in the industrial and quality departments, this success is particularly important.

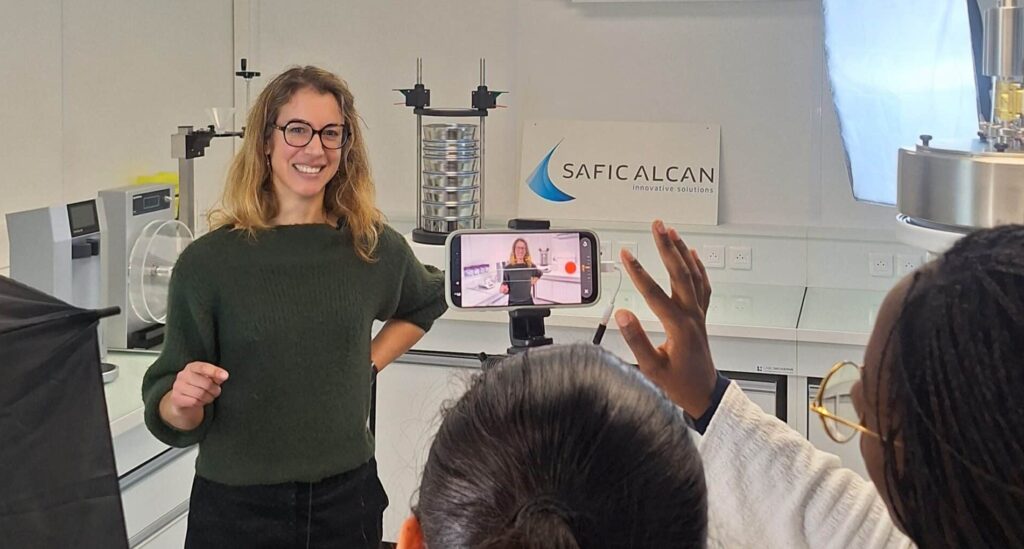

Mathilde Pallandre, Head of Retiers’ Quality department, answers our questions about this major achievement.

Our speaker

Mathilde Pallandre holds an engineering degree in food processing. She has been working in Lactalis Ingredients’ factory of Retiers for over 15 years and has evolved from quality engineer to continuous improvement engineer to finaly Head of Quality department. Thanks to her rich experience, Mathilde is a key player in the Lactalis Ingredients Pharma team.

EXCiPACT and its certification process

What is EXCiPACT?

EXCiPACT is a non-profit, independent, and high-quality third-party Certification Scheme qualifying excipient suppliers based on their Good Manufacturing Practices standards1 . It was developed by the International Pharmaceutical Excipients Council – IPEC – to ensure a safe, reliable, and transparent supply chain.

This certification is not required by the excipients market, though it provides pharma clients with a wealth of information on the production site’s ability to manufacture reliable excipients to formulate their medicines, along with reducing the need for additional audit, thus saving time and money for both the supplier and client.

Lactalis Ingredients Pharma’s factory of Retiers was audited by SGS, a certification body registered by EXCiPACT to assess of the GMP setup in excipient factories2. SGS provided insightful support to our teams regarding best practices to follow. All in all, Retiers’ teams strengthened their continuous improvement policy and developed a better change management approach.

What was the process of the EXCiPACT certification?

Mathilde Pallandre, Head of Retiers’ quality department says:

“The certification process was part of the project to launch lactose manufacturing as a pharma excipient. This project was launched in January 2021 with a team of 2 engineers dedicated to deploying best practices and supporting the teams. Together, we went through the following certification milestones:

- Understanding of the guidelines

- Set up of a steering committee to follow the project

- Qualification and repeatability of the lactose manufacturing process

- Blank audit with an external consultant

- GMP training for Retiers’ teams

- 1st production run for sampling and validation of procedures

- Certification”

EXCiPACT: a successful and rewarding experience

Which teams were involved in this process?

“All the production teams at Retiers were involved, from management to operators, as well as support services such as maintenance, laboratory and continuous improvement.

Lactalis Ingredient’s head office was also involved in the process, in particular the sales, quality, supply chain and marketing departments, but also the quality, logistics and purchasing departments of Lactalis Group.” says Mathilde.

How did we grow from this experience?

“First, we were able to recruit additional human resources who brought a fresh perspective to the project. We also improved our change management process, which now enables us to anticipate evolutions to carry out and better support our teams, especially through training courses. Finally, all the best practices we’ve acquired have enabled us to improve performance across all our activities and workshops.”

Overall, the EXCiPACT certification process was a major achievement for Retiers, who is now proud to prove to our pharma clients the reliability of their production. This experience also benefits the food ingredients manufacturing and Retiers’ other departments, thanks to the best practices implemented over the years of preparation.

More about the manufacture of Retiers

Located in Western France, Retiers is a staple factory for Lactalis Ingredients as it has been producing lactose ever since 1975. In 2017, a state-of-the-art lactose facility was inaugurated there to valorize lactose even further and start producing pharmaceutical quality excipients. Over the following years, the production equipments were tested by producing lactose for the most demanding markets, such as infant or clinical applications. Now that the factory is certified by the biggest infant and clinical nutrition companies, Retiers is ready to supply the excipients market with pharmaceutical grade lactose. To reassure this new market on our capabilities, Lactalis Ingredients Pharma decided to run for the EXCiPACT certification. Learn more about Retiers here .

We sincerely thank our teams in Retiers, Bourgbarré and Laval, and the auditors of SGS for participating to this certification journey and are looking forward to seeing the future of our pharma activity!

Do not hesitate to contact us if you wish to learn more about our quality policy and receive our agreements certifications and statements.

Sources

- What is EXCiPACT? https://www.excipact.org/ ↩︎

- EXCiPACT GMP Certification https://www.sgs.com/en-be/services/excipact-gmp-gdp-certification ↩︎