Nitrosamines, probable human carcinogens, have raised concerns in the pharmaceutical industry. While regulations focus on active ingredients, excipients can also be a source of contamination. Discover the latest detection methods, regulatory updates, and how Lactalis Ingredients Pharma ensures compliance.

The Rising Challenge of Nitrosamines Contamination in Excipients

Could pharmaceutical excipients be a hidden source of nitrosamines contamination? These probable carcinogens have been at the center of regulatory scrutiny since their detection in widely used medications like valsartan and ranitidine. While much attention has been placed on active pharmaceutical ingredients (APIs), recent findings confirm that excipients can also introduce nitrosamines into drug formulations (1).

Between 2024 and 2025, both the EMA and FDA have strengthened compliance measures to address this risk, pushing for enhanced detection methods and stricter raw material sourcing (2,3).

Where Do Nitrosamines in Excipients Come From?

The main sources of nitrosamine contamination in excipients include:

- Residual nitrites found in raw materials, especially in naturally derived ingredients like lactose.

- Agricultural practices and water treatment processes may contribute to nitrite presence in whey-based excipients (2).

- Additionally, manufacturing conditions such as drying, packaging, and solvent recycling can create an environment that promotes nitrosamines formation (3).

While not all excipients present the same level of risk, studies indicate that some, like crospovidone, have significantly higher nitrite levels compared to lactose, which remains below 0.54 ppm (2).

EMA and FDA Regulations: What Has Changed in Recent Years?

To address nitrosamine contamination, regulatory agencies have introduced stricter control measures. The EMA’s 2024 revision of monograph 2034 now requires systematic impurity assessments for excipients, ensuring that manufacturers take proactive steps to mitigate risks (1). Similarly, the FDA’s updated classification of nitrosamines differentiates between traditional nitrosamines (NDMA, NDEA) and NDSRIs (Nitroso Drug Substance-Related Impurities), each with specific acceptable intake (AI) thresholds (2). The upcoming ICH M7 (R2) Guidelines, expected in 2026, aim to harmonize global nitrosamines control strategies, making compliance more streamlined across different markets (3).

For pharmaceutical manufacturers, this means not only meeting stricter analytical requirements but also reassessing supply chain transparency and excipient sourcing to prevent contamination at its origin.

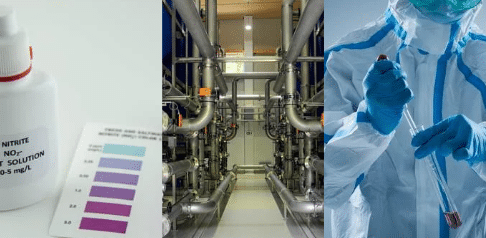

How Are Nitrosamines Detected? The Latest Analytical Advances

With regulations becoming more demanding, analytical methods have evolved to enhance detection capabilities. ATNA (Automated Total Nitrosamines Analyser), introduced in 2024, provides faster and more precise detection by screening multiple samples simultaneously in under 20 minutes (4). Meanwhile, high-resolution LC-MS/MS has improved in accuracy with the integration of QSRR (Quantitative Structure-Retention Relationship) modeling, which enhances the ability to predict nitrosamines retention in drug formulations (5).

In parallel, Ion Chromatography coupled with UV Spectroscopy (IC-UV) has become a go-to method for detecting nitrite residues in excipients, as it offers twenty times higher sensitivity than traditional colorimetric techniques (6).

Preventing Nitrosamines Contamination: A Proactive Industry Approach

Rather than relying solely on detection, manufacturers are implementing targeted prevention strategies. The selection of ultra-low nitrite raw materials is a priority, ensuring that contamination risks are minimized from the outset (3). In addition, some process optimizations such as double crystallization and alkaline washing can help to remove residual amines from excipients, and further reducing the potential for nitrosamines formation (2).

Another key focus is on reinforcing supplier oversight. The adoption of standardized excipient risk assessment questionnaires (IPEC, 2023) has improved supply chain transparency and ensures that manufacturers comply with evolving regulations (4).

Lactalis Ingredients Pharma: Ensuring Compliance and Safety

At Lactalis Ingredients Pharma, ensuring the safety and compliance of pharmaceutical lactose is our top priority. By maintaining full control over sourcing, we favor internally sourced lactose, eliminating contamination risks from external raw materials (2).

Our Retiers production facility is certified ISO 9001, FSSC 22000, and EXCiPACT, ensuring full compliance with pharmaceutical safety and quality standards. We also guarantee a low level of nitrosamines across our pharmaceutical-grade lactose range.

What’s Next? The Future of Nitrosamines Control

As regulatory bodies continue refining their approaches to nitrosamines control, the pharmaceutical industry is expected to integrate more advanced preventive strategies. The development of AI-driven predictive models is gaining traction, offering new ways to forecast nitrosamines formation based on excipient properties and production conditions (5). Furthermore, research into real-time monitoring systems, such as electrochemical sensors capable of detecting nitrosamines instantly, is progressing toward industrial application (6).

With the EMA and FDA moving towards greater harmonization of risk assessment protocols, companies will need to remain agile in adapting their compliance strategies. We remain committed to ensuring the highest safety standards, leveraging cutting-edge analytical methods and process optimizations to guarantee pharmaceutical lactose that meets the most stringent regulatory requirements.

For more details on pharmaceutical lactose safety and regulatory compliance, contact our team or request a sample today.

Sources

- European Medicines Agency (EMA) – Read more

- U.S. Food and Drug Administration (FDA) – Read more

- ICH M7 (R2) Guidelines – Read more

- Innovations in Nitrosamines Detection and Prevention (2024-2025) – Read more

- Advances in Predictive Modeling for Nitrosamines Formation – Read more

- Industry Reports on Real-Time Nitrosamines Monitoring – Read more